Proven, Scalable Solutions for Every Mine

Cat® MineStar™ Solutions

Cat® MineStar™ Solutions

Whether you’re ready to integrate your first basic technology product or well down the path toward autonomous mining, there’s a Cat® MineStar™ Solution for you. MineStar has the ability to track, monitor, automate and manage all types of assets — from people to production machines to light vehicles on site. Whether you deploy a single technology or a multi-purpose solution, you can expect a safer, more productive and more efficient operation.

Surface Technology

Proven on surface mines around the world, MineStar is the mining industry’s most comprehensive and thoroughly integrated suite of technology offerings.

Underground Technology

Underground mining presents special challenges when it comes to safe, efficient operation. That’s why we tailor Cat® MineStar Solutions to your unique needs.

MineStar Edge

Edge is a new technology platform that delivers more connected, integrated, scalable and intuitive products that extend further up and down the value chain.

What is your challenge?

FLEET PRODUCTIVITY

Inconsistent processes. Unskilled operators. Misdirected loads. Long cycle times. Extended machine downtime. These are just a few of the challenges that can have an impact on your productivity — and they’re all challenges that can be addressed by MineStar.

SAFETY

You do all you can to keep your people out of harm's way. MineStar Solutions can help you do more. They increase operator awareness and visibility, help you identify and manage operator fatigue and distraction, alert operators to potential collisions.

EQUIPMENT HEALTH

You want to get the most out of your equipment investment. Staying connected to machines and paying attention to the data they provide is one of the best ways to control costs.

AUTOMATION

If you’re looking for step changes in safety, productivity and efficiency, there’s one solution that will make it happen: Automation. But mining automation isn’t one size fits all.

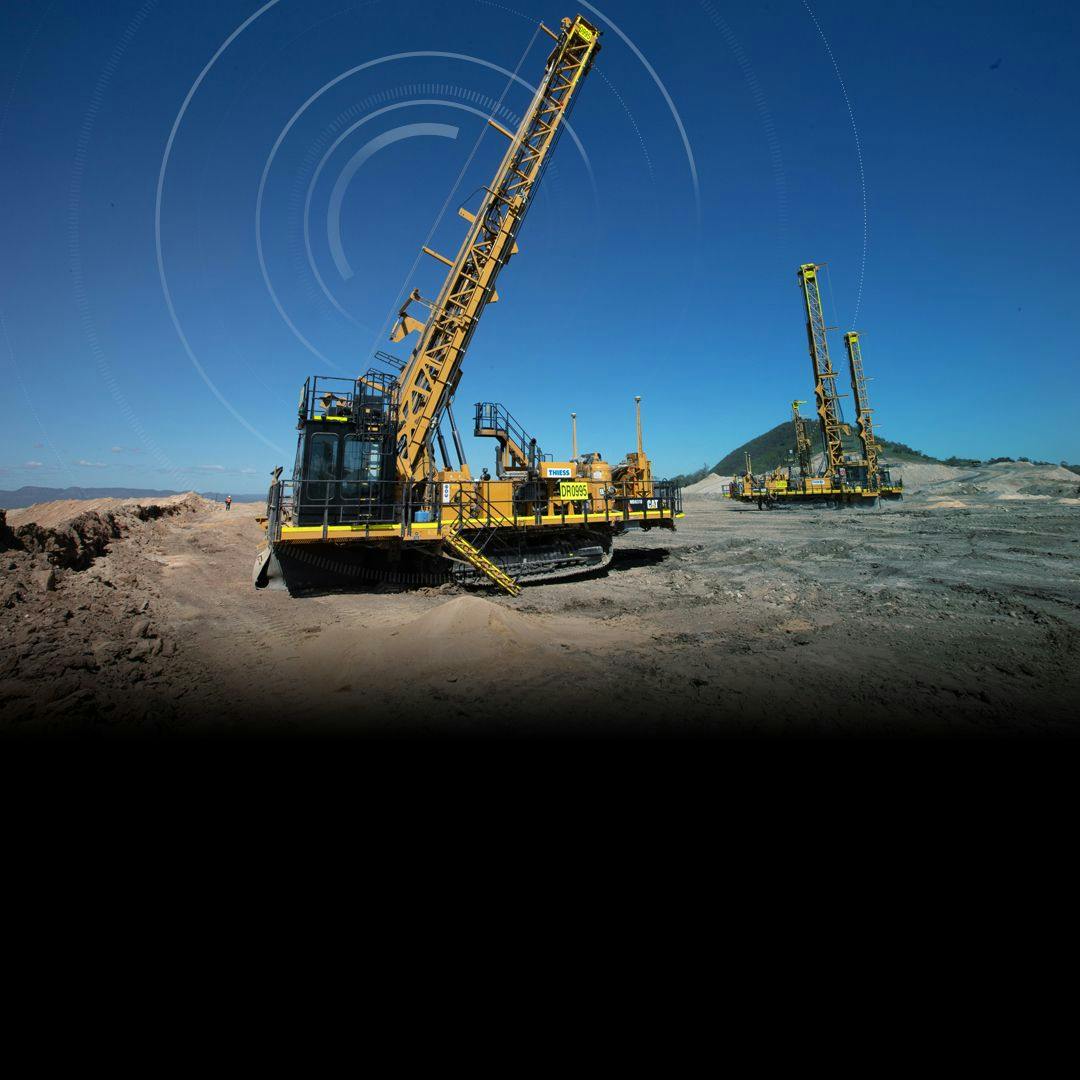

Drilling

Cost-effective, high-precision drilling gets your whole mining value chain off to a good start. And Cat MineStar Solutions can help — from increasing accuracy and consistency to delivering quality fragmentation and better blasthole quality.

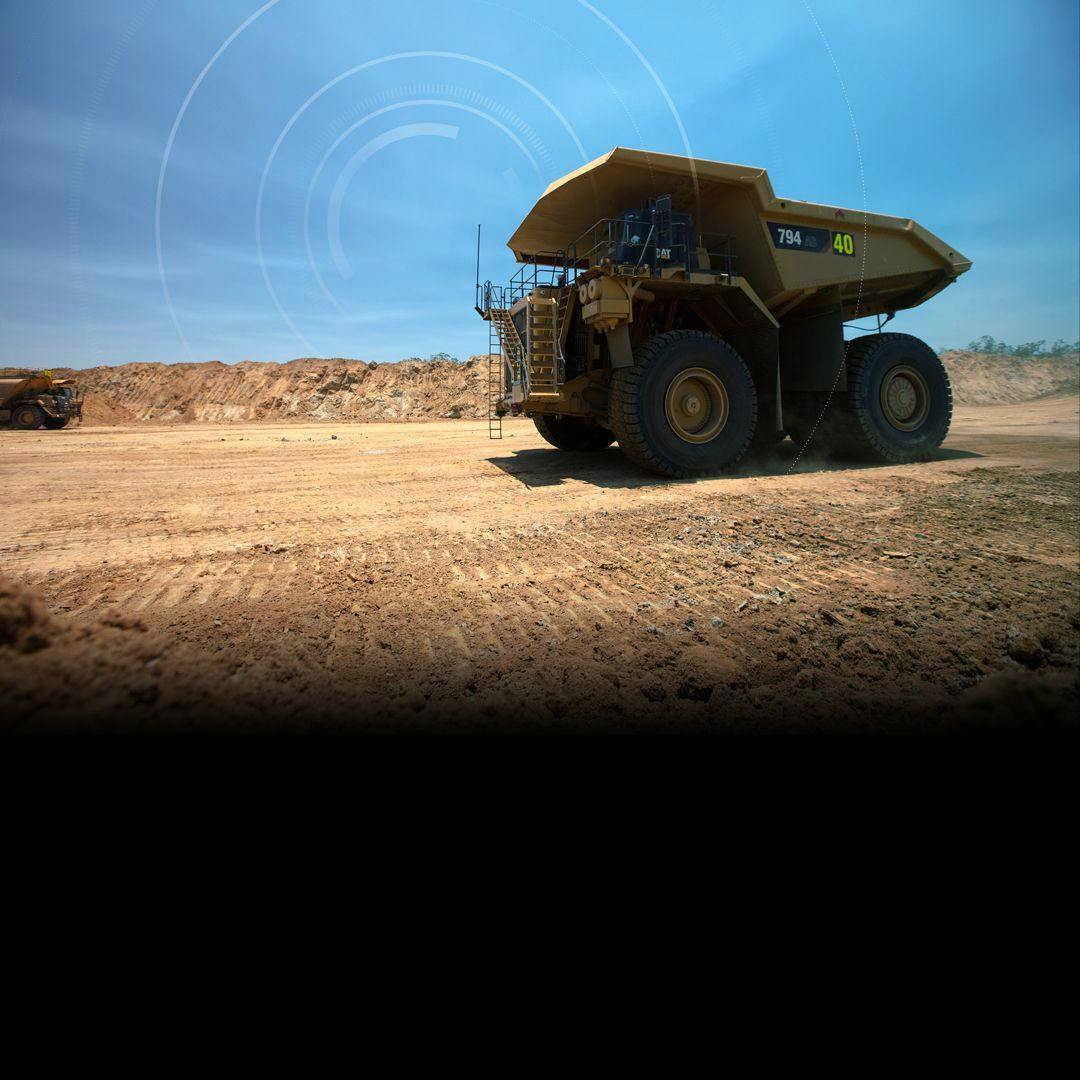

Loading And Hauling

Cat MineStar Solutions keeps your shovels busy and your trucks on the move by helping you maximize payload, manage shifts, identify bottlenecks, measure the volume of material cut and filled, ensure you’re moving the right amount of material

Dozing And Grading

MineStar Solutions for dozing and grading are focused on the operators. They’ll have access to onboard guidance tools and real-time feedback on bench heights, cycle times, volume of material cut and filled, and more.